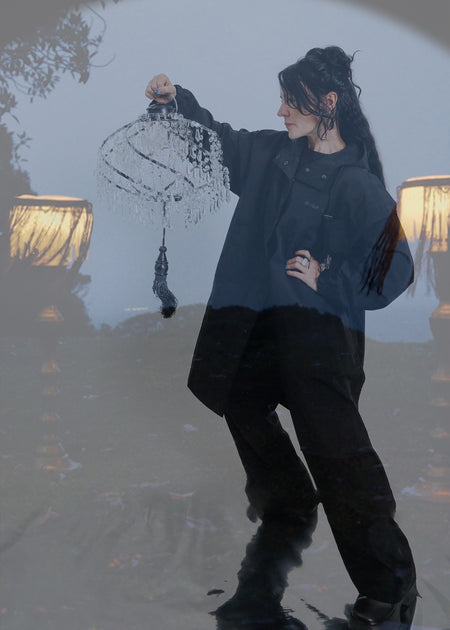

Fashion that endures - Style that Lasts

Our focus centres on creating high quality garments of timeless and durable design and production—to be worn and loved across numerous seasons and trends.

We are committed to making better choices across the business, to improve all of our processes to limit the impact that we have on the environment and always produce product within fair and safe guidelines.

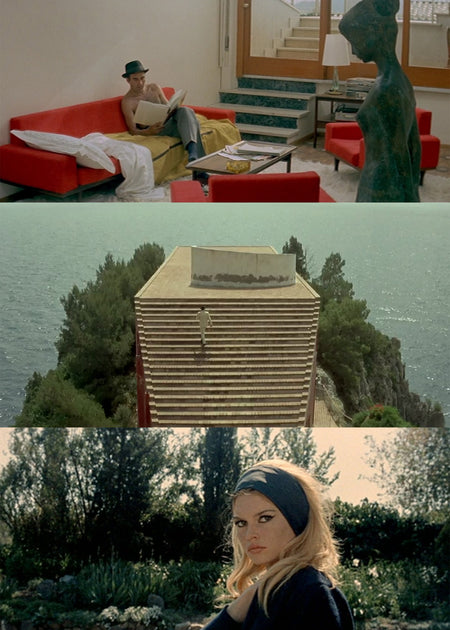

Design

Our collections are thoughtfully designed and curated in our studio in Collingwood, Melbourne, where we oversee every step of the process. We handle our production end-to-end, without outsourcing any part of the CMT (cut, make, trim) process. This ensures we maintain full control over working conditions, guaranteeing that ethical standards are met at every stage.

We prioritise high-quality fabrics in our collections, including natural fibres like cotton, linen, silk, and wool with durable synthetics such as polyester, viscose, and tencel. We are proud to say that we have never, and will never, use fur or exotic leathers in our production. Our design and production process is powered by advanced enterprise technology and reporting tools that provide us with valuable data and insights. This allows us to produce more accurate, smaller quantities with precise size curves, reducing waste and improving fit.

By working on a direct-to-consumer model, we eliminate the middleman, giving us greater control over the entire process. This approach enables us to offer higher-quality, long-lasting products at approachable prices. We are always looking for ways to improve the sustainability of our practices, continually seeking innovative solutions to make our processes more environmentally responsible and ensure a better future for fashion.

Production

Ninety percent of our garments are produced in a family-owned factory in Humen, China, with whom we’ve maintained a strong and trusted relationship for many years. We prioritize fair and ethical working conditions, visiting the factory biannually to ensure that standards are upheld. As ALPHA60’s primary customer, we work closely with the factory team to ensure that these conditions are not only met but consistently improved.

At ALPHA60, we work with small, limited production runs, which helps maintain quality and closely monitor conditions at every stage. We hold high standards for craftsmanship, which requires skilled employees. As a result, wages in our factory are well above the regional minimum, and we ensure that pay increases as skill levels rise. Our commitment to fair compensation means the lowest-paid employee earns twice the minimum wage, with wage increases tied to skill development and experience.

The workforce at our factory is highly skilled, experienced, and trained, ensuring that all work is carried out with precision and care. We have a strict policy against employing underage workers at any factory we partner with. For specialised processes like printing, pleating, and embroidery, we collaborate with trusted independent factories that operate specialised machinery. These external factories are regularly inspected to ensure that their working conditions meet and exceed our ethical standards.

Life cycle

At ALPHA60, we focus on creating high-quality garments with timeless, durable designs that are made to be worn and loved for many seasons, transcending trends. We take pride in how our customers curate their Alpha60 wardrobes, blending new, exciting pieces with their cherished Alpha60 classics for a style that lasts.

Our collections are available for purchase online and in our nine boutiques across Australia and New Zealand throughout each season. At the end of every season, any remaining stock is moved to our local warehouse before being made available again. Past-season styles, samples, and seconds are then sold at our dedicated outlet store in Fitzroy, Melbourne, ensuring that no Alpha60 garment ends up in landfill.

While we’re committed to offering the highest quality garments, we’re equally focused on minimizing our environmental impact and reducing waste. At ALPHA60, we always prioritize repairing garments in-house whenever possible before replacing them, ensuring that no Alpha60 piece goes to waste. This sustainable approach allows us to continue delivering beautiful, lasting products while doing our part for the planet.

Packaging

In the last few years, we have reduced our single use plastics by 90% — implementing a company wide program to eliminate all single use plastics within our production and postage processes.

We will continue to make adjustments and improvements in this space to further reduce our impact on the environment.

Buy Better, Resell Later, Consciously Repeat

We’ve partnered with Airrobe to make reselling and entering the circular economy easy for our customers. By allowing customers to rent and lend high-quality clothing, Airrobe reduces the need for constant production and the environmental impact of overconsumption. It helps extend the life cycle of garments, making fashion more accessible while minimising waste.

For Alpha60, partnering with Airrobe means contributing to a more sustainable, circular model by ensuring their pieces get reused and enjoyed by multiple people, rather than ending up in landfills. This not only fosters a more eco-conscious approach but also encourages the idea of fashion as an investment in long-term, versatile pieces.